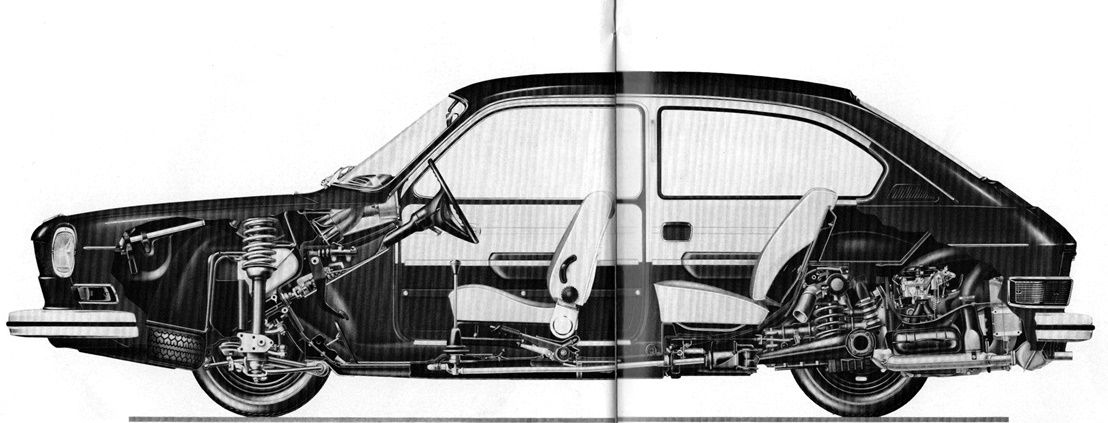

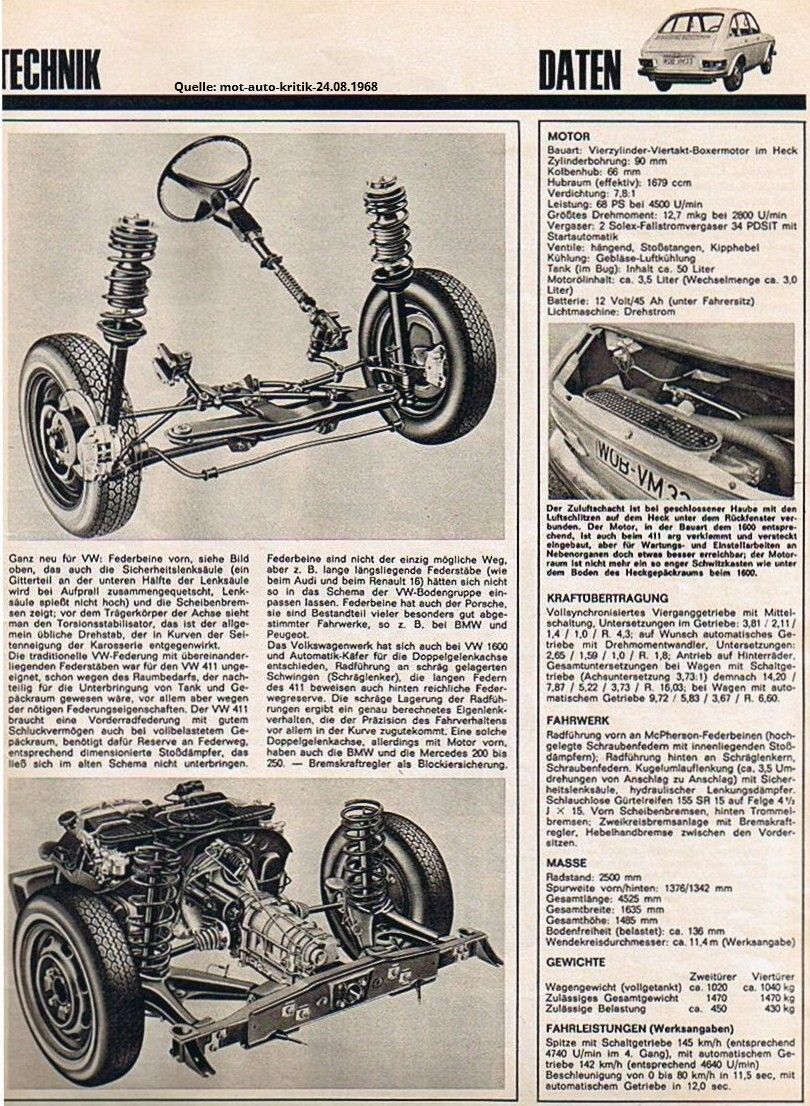

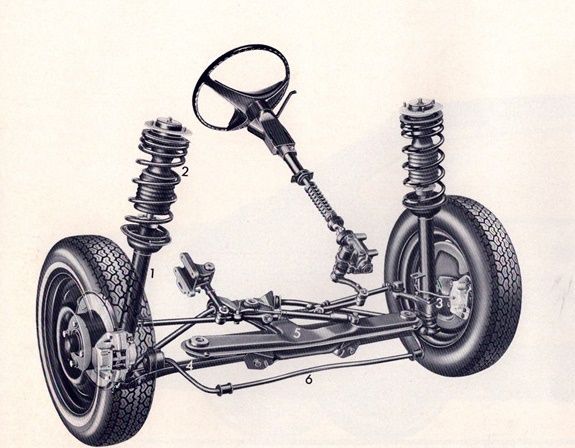

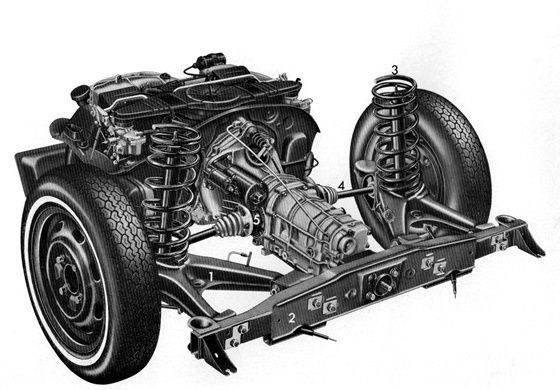

A decisive innovation with great advantages for the use of space in the front end was the front axle construction with spring struts, as also used by Porsche.

The advantages of the design are that the spring struts, which are designed as spring/damper units and also serve as wheel guides, do not take up space in the center of the axle, but are in the fenders.

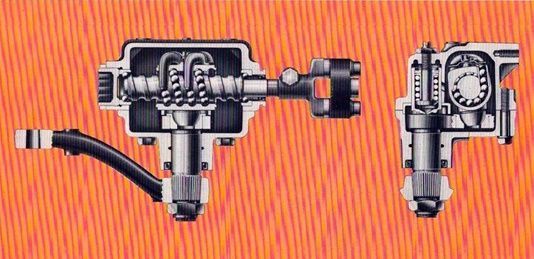

In the middle of the axle there are only very flat parts, such as the push rods, anti-roll bar and the recirculating ball steering, which works fairly directly from lock to lock with 3 1/2 turns of the steering wheel.

Of course, the VW double-jointed axle was used at the rear, which has already weaned the small VWs (with automatic) from oversteering. This axle is also equipped with coil springs on the 411, while it works with torsion bar springs on the other models.

The 411 thus had a largely constant track suspension and no longer had an unwelcome tendency to oversteer.